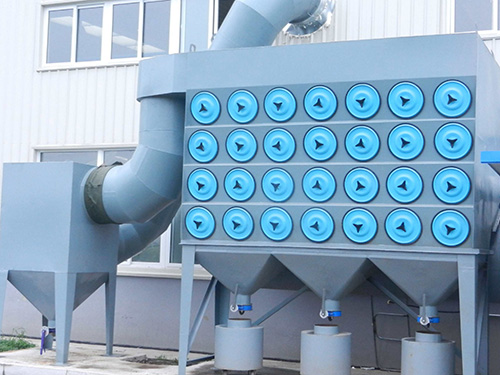

Pulse Filter Cartridge Dust CollectorSuitable For Centralized Treatment Of Welding Fumes, Plasma And Laser Cutting Fumes, Grinding, Polishing, And New Material Processing Fumes. We Can Design Smoke And Dust Capture Devices And Pipeline Systems According To Different On-site Working Conditions Of Customers, And Select The Corresponding Model Of Dust Collector With The Required Air Volume.

Pulse Filter Cartridge Dust Collector Is A Dust Collector That Uses A Filter Cartridge As The Filtering Element And Adopts Pulse Back Blowing. The Filter Cartridge Dust Collector Can Be Divided Into Inclined Insertion Type, Side Installation Type, Lifting Type, Upper Installation Type, Etc. According To The Installation Method. Filter Cartridge Dust Collectors Can Be Divided Into Long Fiber Polyester Filter Cartridge Dust Collectors, Composite Fiber Filter Cartridge Dust Collectors, Anti-static (based On Actual Reports) Filter Cartridge Dust Collectors, Flame-retardant Filter Cartridge Dust Collectors, Membrane Filter Cartridge Dust Collectors, Nano Filter Cartridge Dust Collectors, Etc.

The Structure Of The Filter Cartridge Is Divided Into Four Parts: Top Cover, Metal Frame, Pleated Filter Material, And Base. The Filter Cartridge Composed Of These Four Parts Includes Circular, Flat, And Conical Shapes. The Filter Cartridge Is Folded Into Pleats With Designed Length Of Filter Material, Glued Together At The Beginning And End To Form A Cartridge. The Inside And Outside Of The Cartridge Are Supported By A Metal Frame, And The Top And Bottom Are Fixed With A Top Cover And Base. The Top Cover Has Fixed Bolts And Washers. The Shape Of A Circular Filter Cartridge Or A Flat Filter Cartridge. The Adhesion Between The Upper And Lower End Covers Of The Filter Cartridge And The Protective Net Should Be Excellent, And There Should Be No Defects Such As Delamination, Leakage, Or Sagging; The Metal Parts On The Filter Cartridge Should Meet The Requirements For Rust Prevention; The Outer Surface Of The Filter Cartridge Should Be Free Of Obvious Defects Such As Scratches, Bumps, Burrs, And Burrs.

The Pulse Filter Cartridge Dust Collector Has A Small Volume, Light Weight, Flexible Assembly, And Occupies A Small Space; The Filter Bag Dust Collector Has A Large Appearance, Bulky Volume, And Occupies A Lot Of Space For Installation. Another Advantage Of The Filter Cartridge Dust Collector Is That The Wear Of The Filter Cartridge Is Small, And It Does Not Need To Be Replaced Frequently.

Pulse Filter Cartridge Dust Collector Has The Advantages Of Small Volume, Etc. Due To The Emergence Of New Filter Media And The Improvement Of Dust Collector Design, Filter Cartridge Dust Collectors Have Begun To Be Applied In Dust Removal Engineering, Widely Used For The Purification Of Dusty Gases And The Recovery Of Dust Materials In The Food, Pharmaceutical, Feed, Metallurgy, Building Materials, Cement, Machinery, Chemical, Power, And Light Industry Industries.

During Normal Operation Of The Pulse Filter Cartridge Dust Collector, Dusty Gas Enters The Dust Collector Through The Top Inlet. A Dust Baffle Is Installed To Block Larger Particles Of Dust And Prevent Collision And Wear Of The Filter Cartridge. Fine Dust Is Filtered Through The Filter Cartridge. During This Process, Dust Is Captured On The Outer Surface Of The Filter Cartridge, While Clean Air Enters The Clean Air Chamber Through The Center Of The Filter Cartridge And Is Then Discharged Through The Outlet. When Cleaning The Filter Cartridge, The Control Timer Will Automatically Select One Or More Pairs Of Filter Cartridges For Cleaning. At This Time, The Controller Will Open The Electromagnetic Pulse Valve, And High-pressure Air Will Directly Enter The Center Of The Selected Filter Cartridge To Blow Away The Dust Collected On The Surface Of The Filter Cartridge. Dust Flows In The Direction Of The Main Airflow And Falls Into The Ash Hopper Under The Action Of Gravity.