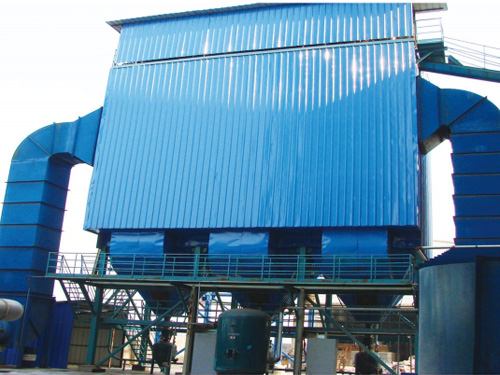

Boiler Dust CollectorThe Function Of The Device Is To Remove Particulate Smoke And Dust From Boiler Fuel And Combustion Emissions, Thereby Significantly Reducing The Amount Of Smoke And Dust Emitted Into The Atmosphere. This Is An Important Environmental Protection Equipment That Mainly Pollutes The Environment And Improves Air Quality.

The Advantages And Characteristics Of Boiler Dust Collectors.

1、 Boiler Dust Collectors Can Effectively Reduce Pollutants Emitted From Boilers, Especially Smoke And Sulfur Dioxide, Without Specific Clinical Effects As The Main Focus. These Emissions Pose Great Harm To The Environment And Human Health, And Boiler Dust Collectors Can Filter Out These Pollutants, Reducing Environmental Pollution And Health Risks.

2、 Boiler Dust Collectors Can Also Improve The Efficiency Of Boilers And Save Energy. During The Combustion Process, Boilers Generate A Large Amount Of Flue Gas And Heat. If These Flue Gas And Heat Are Not Fully Utilized, It Will Result In Energy Waste. The Boiler Dust Collector Can Filter Out Impurities Such As Dust And Smoke In The Flue Gas, And The Purified Flue Gas Can Be Directly Discharged Into The Atmosphere. At The Same Time, It Can Also Recycle The Heat In It, Improve The Thermal Efficiency Of The Boiler, And Achieve The Goal Of Energy Conservation.

3、 Boiler Dust Collectors Also Have The Characteristics Of Compact Structure, Easy Installation, Stable Operation, And Simple Maintenance. Boiler Dust Collectors Usually Adopt Modular Design, Which Can Be Flexibly Combined According To Different Boiler Requirements And Installed Conveniently And Quickly. At The Same Time, The Boiler Dust Collector Operates Stably And Can Maintain Effective Filtration For A Long Time. Maintenance Is Also Very Simple, Just Regularly Clean The Filter Screen.

Boiler Dust Collectors Can Achieve Good Practical Results And Create A Favorable Working Environment. In The Operation Of Boiler Equipment, If Not All Of Its Fuel Is Burned, Small And Small Combustible Particles And Volatile Substances Will Mix Together And Be Discharged, Causing Thick Black Smoke To Appear At The Chimney Outlet. The Unpurified Flue Gas Emitted From Such Chimneys Contains A Large Amount Of Sulfur Dioxide And Dust. If The Boiler Flue Gas Dust Removal Equipment Is Not Used For Filtering And Emission, This Flue Gas Will Cause Serious Pollution To The Atmosphere, Damage The Environment, Affect People's Health, And Also Harm Plant Growth. The Role Of Boiler Dust Collectors Can Solve The Problem Of Atmospheric Pollution Caused By Smoke And Dust Emissions From Many Coal-fired Enterprises. They Can Also Effectively Remove Or Replenish Dust Particles In The Flue Gas Emitted By Coal-fired Boilers, And Greatly Help Improve The Air Environment Quality.

The Dust Removal Equipment Used In Boiler Dust Collectors Includes Mechanical Dust Collectors, Bag Filters, Electrostatic Precipitators, And Wet Dust Collectors. However, Each Dust Removal And Purification System Has Its Own Technical Advantages And Disadvantages, And Suitable Dust Removal Facilities And Processes Should Be Selected According To The Actual Situation. Mechanical Dust Collector Usually Refers To A Device That Uses The Action Of Mass Force (gravity, Inertia Force, Centrifugal Force, Etc.) To Separate Particulate Matter From Airflow. It Includes Gravity Settling Chambers, Inertial Dust Collectors, And Cyclone Dust Collectors. A Bag Filter Is A Dust Removal And Purification Facility In Which Dust Containing Gas Enters A Cylindrical Filter Bag From The Bottom, Passes Through The Pores Of The Filter Material, And The Dust Is Captured On The Filter Material. The Clean Air Passing Through The Filter Material Is Discharged Through The Outlet, And The Dust Deposited On The Surface Of The Filter Material Can Be Removed From The Surface Of The Filter Material Under The Action Of Mechanical Vibration And Ultimately Fall Into The Ash Hopper.